Case IH 500/500T and New Holland 2080/2085 Air-Seeder Modifications.

The Case IH 500 and 500T air-seeders were released in 2013. They offer many features to help with soil/residue cutting and seed placement. One feature we really like is the parallel linkage within the opener assembly. The parallel linkage allows the opener to travel a total of 20” (8.5” up and 11.5” down from the typical working position) and this allows the opener a huge amount of terrain following ability, plus the benefit of allowing all the opener features to raise and lower together. By comparison, the John Deere 50/60/90 series radial arm opener design changes the angle of the boot, in addition to closing wheel arm pressure and firming wheel arm pressure as the opener arm moves up or down.

�

The Case IH 500 and 500T air-seeders were released in 2013. They offer many features to help with soil/residue cutting and seed placement. One feature we really like is the parallel linkage within the opener assembly. The parallel linkage allows the opener to travel a total of 20” (8.5” up and 11.5” down from the typical working position) and this allows the opener a huge amount of terrain following ability, plus the benefit of allowing all the opener features to raise and lower together. By comparison, the John Deere 50/60/90 series radial arm opener design changes the angle of the boot, in addition to closing wheel arm pressure and firming wheel arm pressure as the opener arm moves up or down.

�

Narrow Gauge Wheels

On the standard Case IH 500 and 500T air-seeders, we have seen that the factory fitted 4.5 x 16” gauge wheel assemblies do climb up on heavy residue, especially when no-tilling into heavy corn residue. This can and often does result in inconsistent seeding depth on account of the gauge wheel lifting the disc out of the ground. A good example is illustrated right and just like on the John Deere drills and air-seeders, a narrower gauge wheel will helps avoid around half of this residue. Narrow gauge wheels fit on the 500 and 500T and more information is contained within the link below. New Closing System

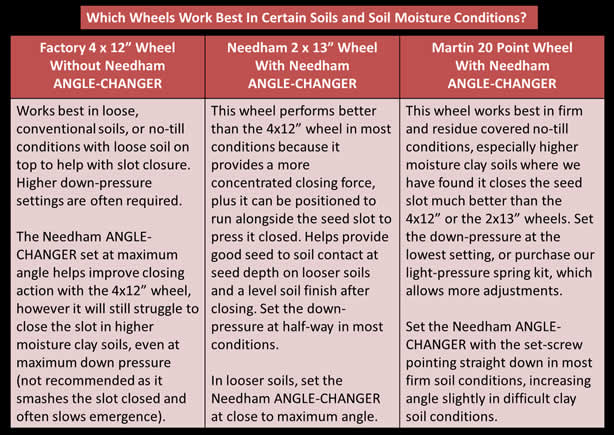

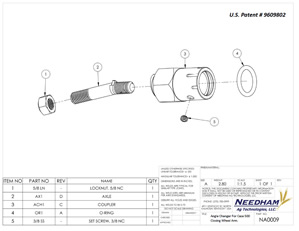

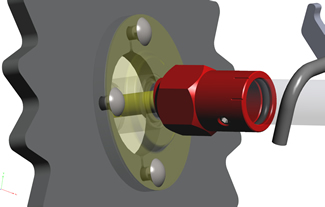

To best serve growers within these different soil conditions, we recognized the importance of being able to adjust the closing wheel angle. With this in mind, we developed and refined our new Needham Ag ANGLE-CHANGER (Patent Number 9609802). It’s a simple coupler which mounts around the factory closing wheel arm assembly to allow growers to change the closing/compound angle of the closing wheel. Our ANGLE-CHANGER features a 11 degree angle on the outer housing, together with a timed axle, also with an 11 degree angle. When the ANGLE-CHANGER is installed, it can be rotated through around 90 degrees to increase or decrease the closing/compound angle. Once the desired angle is obtained, the set screws can be torqued to lock them it in place. We don’t expect growers to change the angle of the ANGLE-CHANGER once ideal closing wheel angle is obtained. However, every region will likely require slightly different settings to allow the closing system to perform best, so we have a list of settings and recommendations to help growers obtain the best closing wheel action for their soil conditions. During the spring of 2014, we tested our ANGLE-CHANGER on 4 different Case IH 500’s, one 500T and one New Holland 2085. The conditions ranged from wet no-till conditions with heavy residue, all the way through dry no-till soils, through to minimum tillage and conventional conditions. The ANGLE-CHANGERS were also tested at different speeds on different soil types and different seeding depths. We also evaluated different spring settings and different springs. We also tested and compared different closing wheels on our ANGLE-CHANGER during testing to help determine which ones perform best within specific soil conditions.

See our new ANGLE-CHANGER working in the field in our youtube video below

See the 20 Point Crumbler Wheels In Action On John Deere And Case IH Air-Seeders.New Screen for 500T Hopper

We have just released a new screen for the hopper of the Case IH 500T and New Holland 2085. Without a screen, some growers reported small pieces of paper (and other foreign material) gets into the metering rollers, seed tubes or seed boots, blocking them up. To help eliminate this problem, our new heavy duty screen inserts into the hopper of all the 500T and 2085 series air-seeders and allows seed to easily flow through, while catching most of the foreign material. The screen allows the lid to close and latch using existing rubber latches. For more information, please call 270-785-0999 or email us Spring Spacers For Case IH 500/500T and New Holland 2080/2085.jpg)

The older Case-IH SDX Air-Seeder had a very good feature which was unfortunately not continued on the new 500/500T or 2080/2085 series. This feature was the ability to adjust down-pressure individually on each opener, by simply pulling a pin and selecting one of the 3 hole positions as illustrated right. This feature was most useful when trying to seed the same depth into tractor or air-cart wheel tracks. Wheel tracks are often lower and the soil is more compacted, thus requiring more down pressure in those rows. Depending on the tire configuration and row spacing, around 8-14 openers were often set in the maximum down pressure setting while all the others across the seeder were set in the medium position. Some growers using the 500/500T and 2080/2085 have reported that they have struggled to achieve consistent soil penetration behind wheel tracks, especially in softer soils. So to improve this situation we designed new spring spacers, and we now have them available. Our spring spacers match the profile of the cast spring housing to compress the spring by an additional ½” which adds around 100 lb of down pressure per row. Installation is easily achieved by unscrewing the bolt which holds the spring assembly together and inserting the spacer into the lower end of the assembly, between the spring and the lower housing. Once installed, tighten the locking bolt back up. � Seed Brakes For Case IH 500/500T and New Holland 2080/2085

As air-seeders get wider, higher fan speeds are required to consistently convey seed out to the wings. Higher fan speeds generate more air volume and also have a tendency to cause some of the seeds to blow out of the seed slot, especially when seeding smaller seeds such as canola. When growers apply in-row fertilizer, the fan speeds have to be increased further, adding to the risk of seeds (and fertilizer) being blown out of the seed slot. We now have Seed Brakes available for the Case-IH 500/500T and New Holland 2080/2085 air-seeders to help reduce or eliminate this problem. Seed Brakes are basically a perforated stainless steel housing that allows most of the air to evacuate through the housing, rather than venting 100% of the air into the seed slot. This venting through the seed brake allows seed (and fertilizer) to fall to the ground by gravity, similar to what we used to see with the older box drills. When a clean seed slot is created, the seed brakes help drop seeds down into the bottom of the seed slot, rather than a random position in and out of the seed slot without the seed brake, especially at higher fan speeds.

Seed Brakes are quickly and easily installed by clamping the Seed Brake to the top of the plastic seed tube and inserting the 1 1/4” seed hose into the top. Seed Brakes are designed to work with seeds greater than 2mm in diameter. So they can be used with small seeds such as canola, oilseed rape and mustard.�

Seed Brakes feature an internal baffle which has been proven to improve seed distribution in the row and helps separate out clumps of seed. This is especially beneficial when seeding small seeds like mustard, canola or flax which tend to be delivered in clumps. For more information, together with pricing – please click the link below. |

We were approached by growers and dealers to design a better closing system for the Case IH 500/500T and New Holland 2080/2085 back in early 2013. This was based on the fact that these seeders often struggled to close the seed slot consistently in certain soil conditions and variable emergence often resulted. So, during the spring of 2013 we began testing different wheels on a Case IH 500T. During initial testing we quickly found the angle of the factory closing wheel wasn’t great enough to consistently close the seed slot in in higher moisture soils, especially when no-tilling into clay soils at greater seeding depths. While testing different wheel options, we quickly concluded that a much greater closing wheel angle (compared to the factory assembly) was required within these damp, residue covered no-till conditions, and only a slightly increased closing wheel angle (compared to the factory assembly) would be required in regions with looser soils, such as long term no-till conditions or within areas using minimum till.

We were approached by growers and dealers to design a better closing system for the Case IH 500/500T and New Holland 2080/2085 back in early 2013. This was based on the fact that these seeders often struggled to close the seed slot consistently in certain soil conditions and variable emergence often resulted. So, during the spring of 2013 we began testing different wheels on a Case IH 500T. During initial testing we quickly found the angle of the factory closing wheel wasn’t great enough to consistently close the seed slot in in higher moisture soils, especially when no-tilling into clay soils at greater seeding depths. While testing different wheel options, we quickly concluded that a much greater closing wheel angle (compared to the factory assembly) was required within these damp, residue covered no-till conditions, and only a slightly increased closing wheel angle (compared to the factory assembly) would be required in regions with looser soils, such as long term no-till conditions or within areas using minimum till.

Our ANGLE-CHANGER features a tapered outer housing with an 11 degree angle. The axle also has a 11 degree angle with a “D” shape to time the axle with the housing. As the coupler is rotated, the closing/compound angle can be increased beyond the factory closing wheel angle to best suit soil type and soil moisture conditions. Once the desired angle is obtained it can be locked in place with the set screw. We also added a rubber seal to keep dust and moisture out of the coupler and timing marks to help position all the ANGLE-CHANGERS the same.

Our ANGLE-CHANGER features a tapered outer housing with an 11 degree angle. The axle also has a 11 degree angle with a “D” shape to time the axle with the housing. As the coupler is rotated, the closing/compound angle can be increased beyond the factory closing wheel angle to best suit soil type and soil moisture conditions. Once the desired angle is obtained it can be locked in place with the set screw. We also added a rubber seal to keep dust and moisture out of the coupler and timing marks to help position all the ANGLE-CHANGERS the same.

.jpg)

.jpg)

Product Guide

Product Guide